-

-

Product

-

-

-

Solution

Solutions

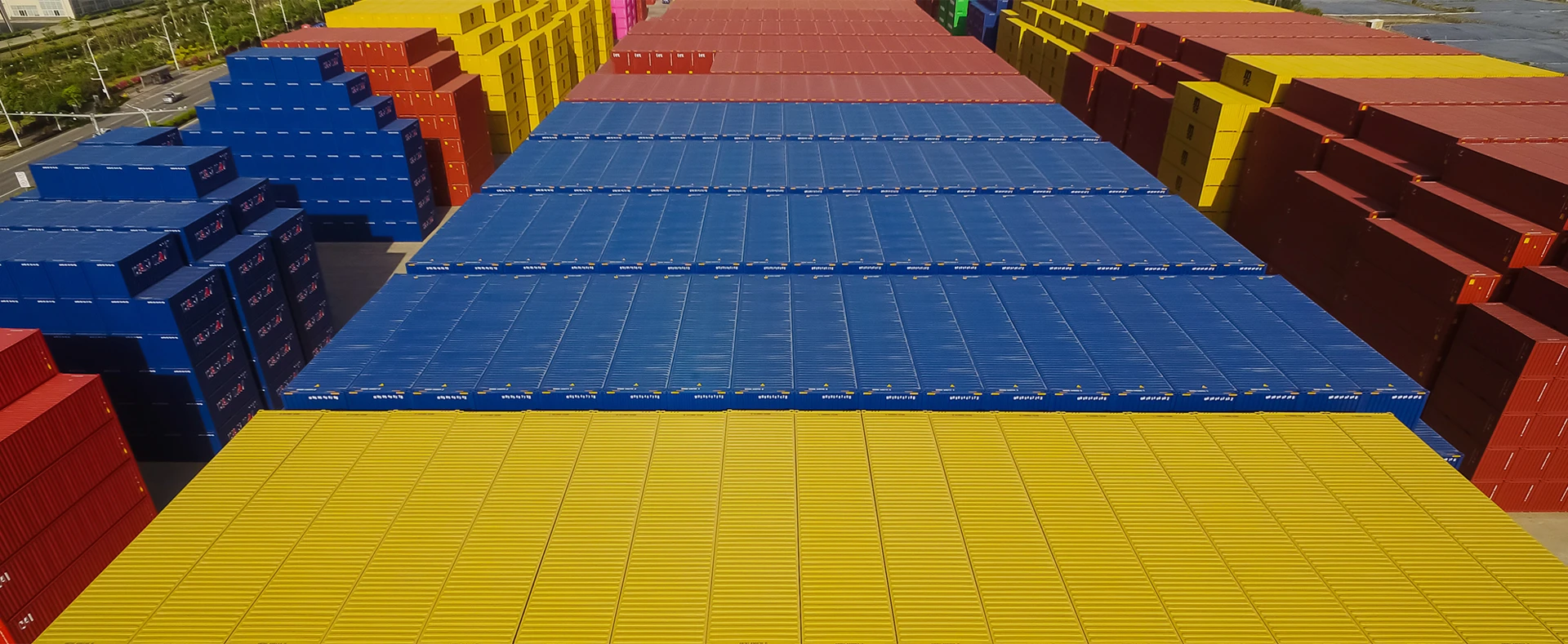

Energy storage system equipment

Dedicated to providing global customers with reliable and efficient logistics transportation equipment and timely, professional lifecycle services.

Overview of Energy Storage Business

Energy Storage Container Body

- The energy storage container body includes: container shell + container insulation layer + battery tray + reserved mounting plate;

- Container sizes include, but are not limited to: 20-foot standard energy storage container bodies, 45-foot standard energy storage container bodies, 30-foot non-standard energy storage container bodies, and other customized sizes of energy storage container bodies;

Semi-integrated Energy Storage Container

- Based on the energy storage container body, it includes the supply and installation of fire protection and lighting monitoring systems, the supply and installation of auxiliary power distribution systems, the installation of liquid cooling units and pipelines, and the pre-laying of harnesses.

- Customer Responsibilities: Electrical box installation, cable harness connection, installation of other equipment, EOL testing, capacity testing, etc.

Fully Integrated Energy Storage Container

- Based on the semi-integrated energy storage container, it includes the installation of customer power supply boxes, connection of cable harnesses, installation of all equipment, EOL testing and capacity testing of the entire container, reaching a state that can be directly sent to the project site.

Container structure & CSC classification society certification

Integrated production & testing equipment

In order to better support the integrated installation and testing of energy storage containers, and to improve product consistency and reliability, the company has invested heavily in automated and advanced production assembly and testing equipment,

While ensuring product quality, it has significantly improved production efficiency.

Insulation resistance tester

Air tightness tester

Digital multimeter

Digital multimeter

Digital multimeter

Electrical box hoisting equipment

Short electrical box installation mold

Electrical box installation robot

Torque wrench

Wireless tightening control

Automated tightening record system

Airtight testing room and automatic liquid injection machine, which improve production efficiency while ensuring the stability of the liquid injection process.

Automated waterproof testing room, designed according to the GB/T4208-2017 standard for enclosure protection grades (IP code), realizing automated waterproof testing, enhancing the reliability and authority of waterproof testing.

Charging and discharging testing equipment

- The testing area is equipped with one 4-channel independent 1725x4KVA intelligent capacity testing equipment;

- Up to 4 20-foot liquid-cooled energy storage containers can be simultaneously supplied for capacity testing.

- Automated energy storage testing platform software, which realizes fully automated operation after pre-setting the termination conditions according to customer recipes;

- Supports 1000V and 1500V switching;

- Supports CAN communication, 485 communication, dry node, and serial communication.

R&D experience

Insulation resistance tester

Digital multimeter

- It has the ability to independently research and develop and optimize the structural system and electrical system of energy storage containers. It also cooperates with third-party research institutes to conduct thermal management simulations. There are more than 40 R&D technicians;

- Currently, the Fujian base has 46 invention patents and utility model patents of various types, covering all aspects of energy storage container production and integration;

- In 2024, it is planned to apply for 20 patents per quarter to ensure the leading edge of R&D and production technology.

Product Introduction

Skid-type AC and DC integrated

AC/DC integrated energy storage container

Electric Boat Energy Storage Container

Small-sized Energy Storage Container

Frame-type Energy Storage Container

Main Partners

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Follow us